Fused Deposition Modeling (FDM)

Innovation is the driving force behind progress. One technology that stands at the forefront of this transformation is Fused Deposition Modeling (FDM) 3D printing. This advanced technique has redefined the way we design, prototype, and produce, offering an array of advantages for industries seeking precision, efficiency, and versatility. This blog delves into the intricacies of FDM 3D printing, examining its significance and the profound impact it has on diverse sectors.

Decoding FDM 3D Printing

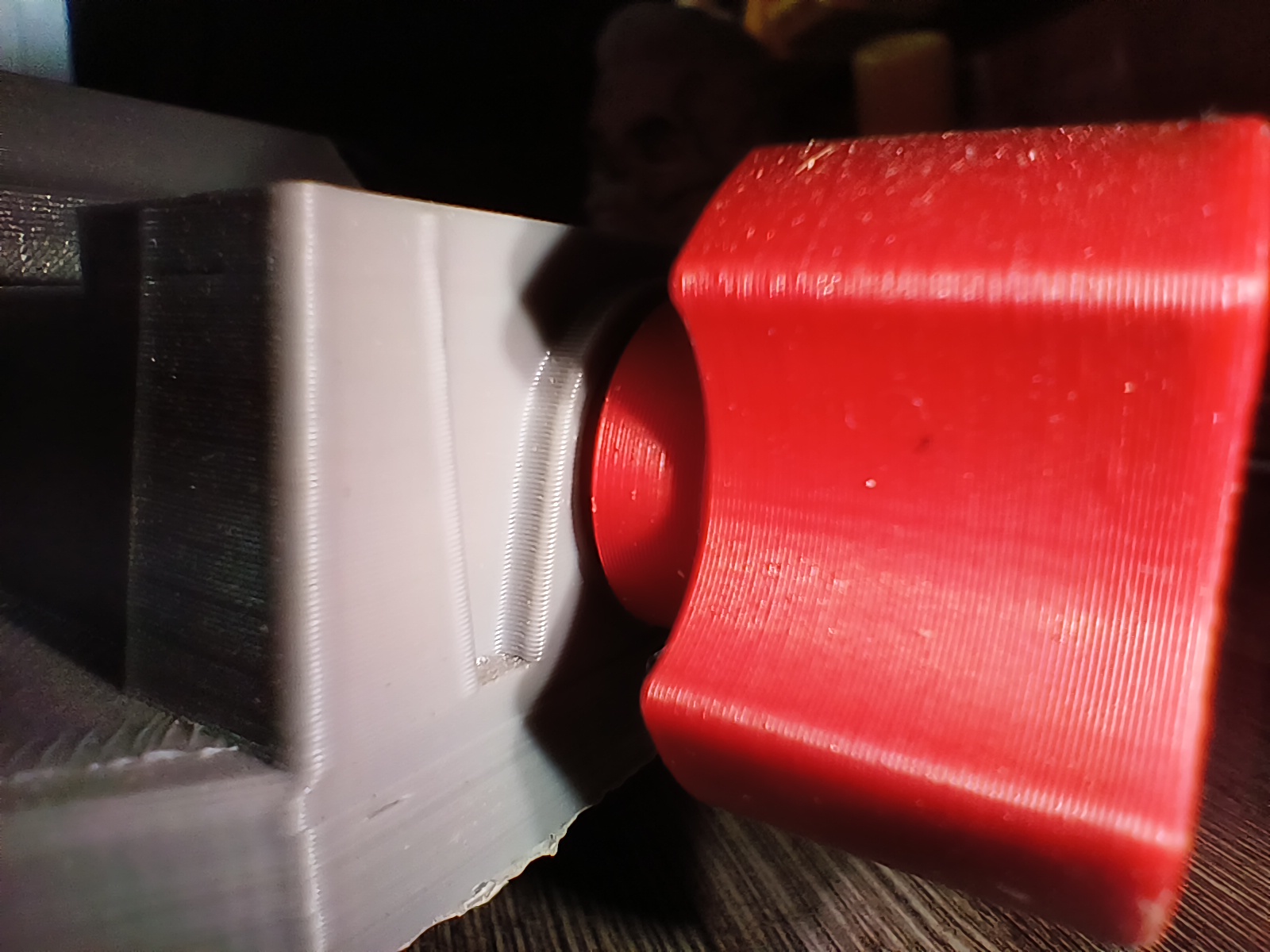

At its essence, FDM 3D printing is an additive manufacturing process that constructs objects layer by layer using a thermoplastic filament. This filament is heated to a precise temperature, then extruded through a fine nozzle, creating intricate patterns that solidify upon contact. This layering process continues until the entire object is formed, resulting in a physical manifestation of the original digital design.

Precision: The Cornerstone of FDM 3D Printing

FDM 3D printing’s hallmark lies in its ability to deliver precision. It offers remarkable accuracy in recreating intricate geometries and fine details, often surpassing the capabilities of traditional manufacturing methods. This level of precision is of immense value to industries where dimensional accuracy and intricate design replication are paramount, such as aerospace and medical device manufacturing.

Efficiency in Design Iteration

In a world where agility is synonymous with success, FDM 3D printing introduces a paradigm shift in design iteration. Traditional manufacturing methods often entail time-consuming and costly tooling adjustments for design changes. In contrast, FDM 3D printing allows for rapid prototyping and iteration without the need for extensive retooling. This efficiency not only accelerates product development but also empowers engineers to fine-tune designs swiftly and cost-effectively.

Material Diversity: Meeting Varied Needs

FDM 3D printing’s versatility extends to its material options. It supports a wide range of thermoplastic materials, each tailored to specific mechanical, thermal, or chemical requirements. This material diversity allows for the creation of components optimized for a variety of applications. From functional prototypes to end-use parts, FDM 3D printing offers a comprehensive solution for industries spanning automotive, consumer electronics, and beyond.

Innovative Production with FDM

The technology’s impact is not confined to prototyping alone. FDM 3D printing is increasingly embraced for low-volume production and customized manufacturing. Its capacity to produce complex geometries and tailored designs on-demand offers manufacturers a competitive edge. This transition from prototyping to production opens doors to responsive manufacturing practices that cater to evolving market demands.

A Sustainable Approach

Sustainability is a driving force in modern manufacturing strategies, and FDM 3D printing aligns seamlessly with this ethos. Unlike traditional subtractive methods that generate significant waste, FDM 3D printing is additive, utilizing only the required material. This reduction in waste not only enhances resource efficiency but also contributes to a greener, more environmentally conscious approach.

Collaborate with IOX Creative 3D Printing for FDM Excellence

As pioneers in advanced manufacturing, IOX Creative 3D Printing is committed to unlocking the potential of FDM 3D printing for your business. Whether you’re seeking precise prototyping, functional end-use parts, or innovative production solutions, our FDM 3D printing services are tailored to meet your unique requirements.

Join us in shaping the future of manufacturing. Contact IOX Creative 3D Printing to explore the transformative possibilities of FDM 3D printing for your industry. Together, we’ll redefine precision, efficiency, and innovation in your domain.